Custom Injection Molding of a Delrin Actuator for the Connector Industry

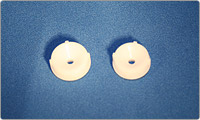

An electronics client approached LOR-TECH Plastics, LLC for the molding of an actuator that would be used within an electrical connector application. For this actuator, the client specified using Delrin® acetal resin because it bridges the gap between metals and ordinary plastics with its dimensional stability and fatigue resistance. We used an existing mold to create the .400" long actuator that had an outer diameter of .100". We have also produced actuators in six other sizes for this client. An electronics client approached LOR-TECH Plastics, LLC for the molding of an actuator that would be used within an electrical connector application. For this actuator, the client specified using Delrin® acetal resin because it bridges the gap between metals and ordinary plastics with its dimensional stability and fatigue resistance. We used an existing mold to create the .400" long actuator that had an outer diameter of .100". We have also produced actuators in six other sizes for this client.

LOR-TECH Plastics, LLC has the expertise to produce injection molded components in a variety of plastic materials across a broad range of industries in. Please contact us to learn more about our services and offerings.

Injection Molding of a Delrin Actuator Project Highlights

| Product Description |

|

This delrin actuator is used as a within an electrical connector application. |

|

| Capabilities Applied/Processes |

|

Primary:

Injection Molding |

Secondary:

Utilized Existing Mold

Maintain and Store Mold | |

|

| Overall Part Dimensions |

|

| Length: .400" |

O.D.: Ø.100 | Also Manufactured in 6 Different Sizes |

|

| Material Used |

|

Delrin |

|

| Material Finish |

|

White |

|

| In process testing/inspection performed |

|

100% Dimensional Inspection |

|

| Industry for Use |

|

Connector |

|

| Turn Around Time |

|

2 to 3 Weeks |

|

| Delivery Location |

|

United States |

|

| Standards Met |

|

Customer supplied print, 2D CAD Drawing |

|

| Product Name |

|

Delrin Actuator |

back to top |

Print This Page

Print This Page

An electronics client approached LOR-TECH Plastics, LLC for the molding of an actuator that would be used within an electrical connector application. For this actuator, the client specified using Delrin® acetal resin because it bridges the gap between metals and ordinary plastics with its dimensional stability and fatigue resistance. We used an existing mold to create the .400" long actuator that had an outer diameter of .100". We have also produced actuators in six other sizes for this client.

An electronics client approached LOR-TECH Plastics, LLC for the molding of an actuator that would be used within an electrical connector application. For this actuator, the client specified using Delrin® acetal resin because it bridges the gap between metals and ordinary plastics with its dimensional stability and fatigue resistance. We used an existing mold to create the .400" long actuator that had an outer diameter of .100". We have also produced actuators in six other sizes for this client.